Excellent quality Grinding Plate - 200MM Resin Polishing Buff for Granite – Jingstar

Excellent quality Grinding Plate - 200MM Resin Polishing Buff for Granite – Jingstar Detail:

DESCRIPTIOIN

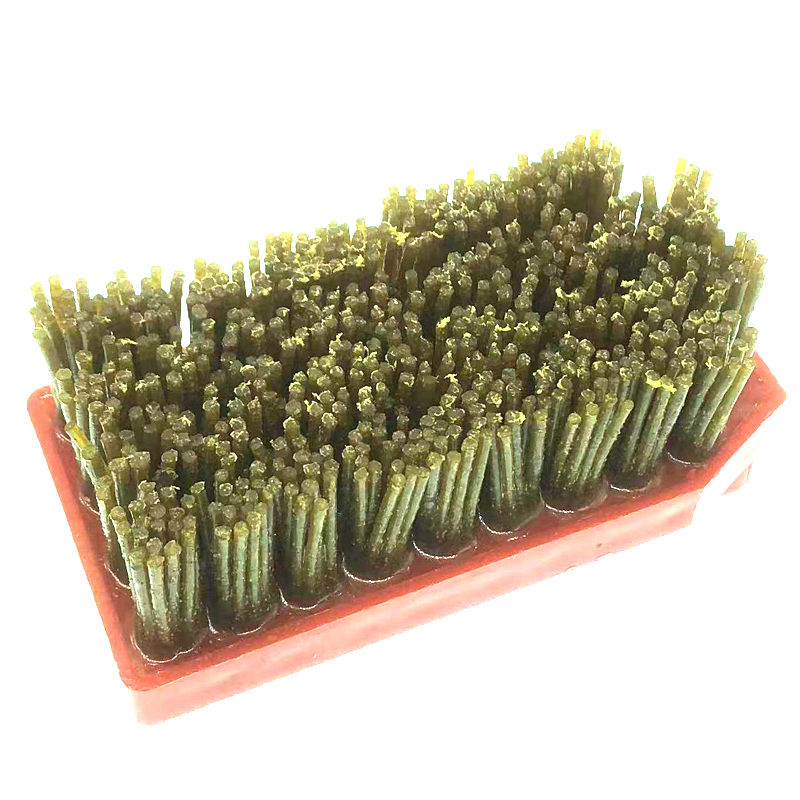

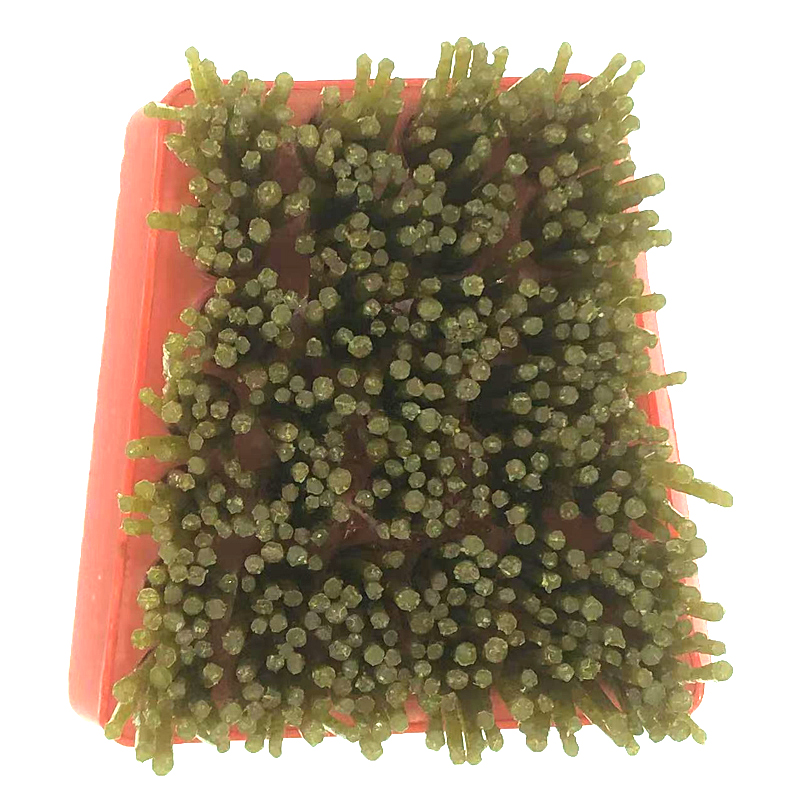

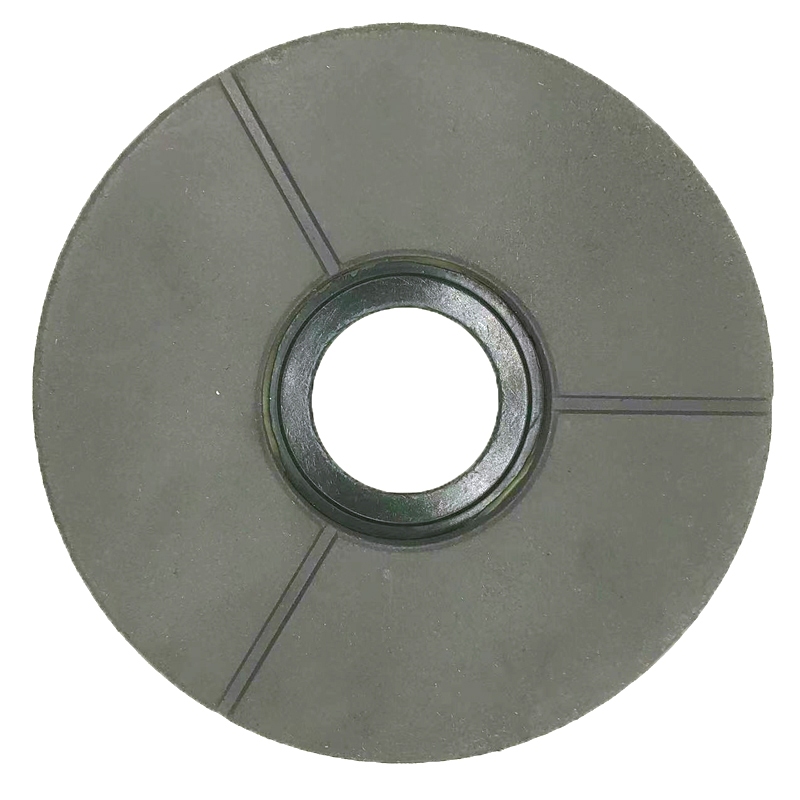

200MM Resin Polishing Buff for Granite for Granite is working on single head polishing machine and automatic polishing machine.resin polishing buff has high sharpness, high gloss polishing and long lifespan. Resin polishing buff is mainly used for high gloss fine granite polishing after using the metal grinding disc of calibration and resin pads, we have completely grit size of resin polishing disc which available from 500# 800# 1000# 1500# 3000#, after 3000#, the buff is final step required which is working for high gloss finishing. There are three color of pads, white polishing buff, red polishing buff and black polishing buff. White polishing buff is used for light color of granite slab, red polishing buff is used for red color of granite slab and black polishing buff is used for dark and black granite slab.

200mm resin polishing buff for granite is popular using on chinese automatic polishing line such as Henglong, Shengda, Keda etc.

Welcome to write to us, we will provide you best working solution.

FEATURES

Reasonable price with high quality

Stable quality with long life span

High fixing strength

Easy to use on automatic polishing line and single head polishing machine

High gloss finishing for granite slab

|

Products details |

||||

|

Diameter |

Desctiption |

Grit size |

Purpose |

|

|

8″/200mm |

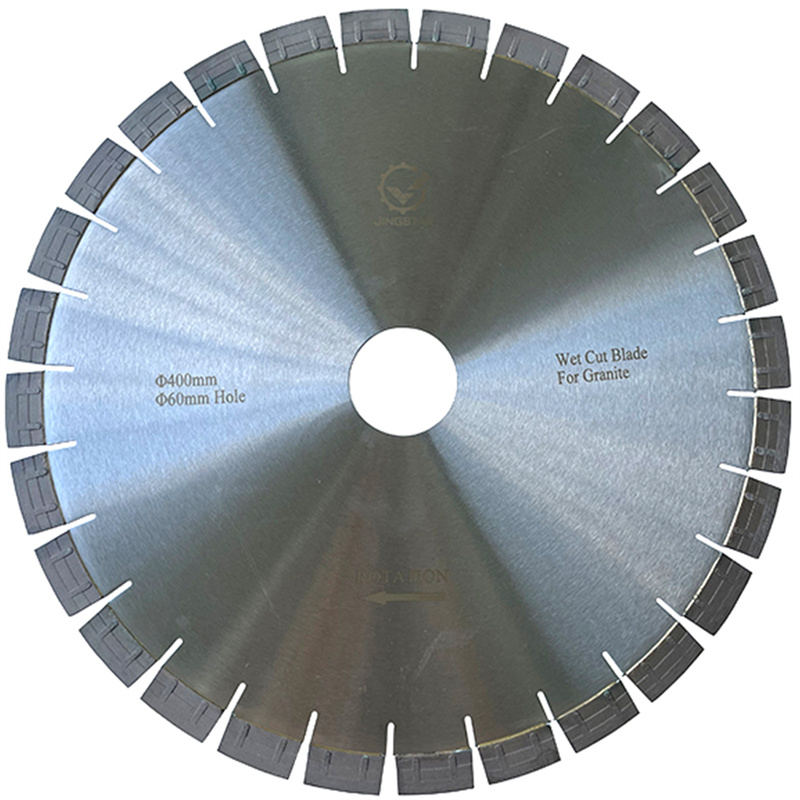

Metal Disc |

50# 200# 400# |

Granite Slab |

|

|

|

|

|

|

|

|

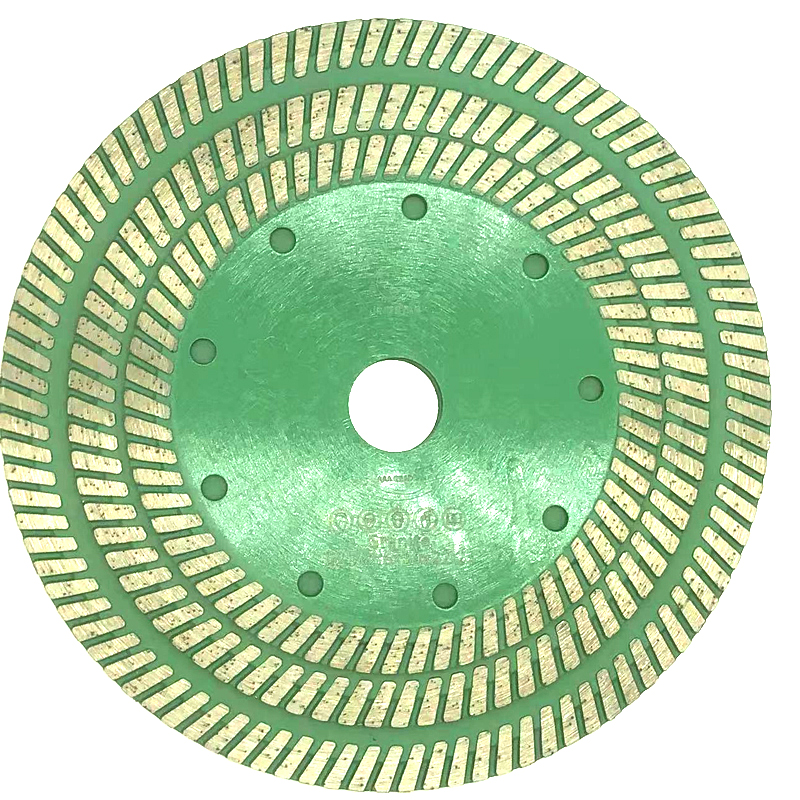

9”/230mm |

Resin Disk |

800#,1000#,1500# |

Granite Slab |

|

|

|

|

|

|

|

|

9”/230mm |

Buff |

White, Black, Red |

Granite Slab |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Suggested sequence for automatic polishing line |

||||

|

Sequence |

12 heads |

16 heads |

20 heads |

24 heads |

|

1 |

50 |

50 |

50 |

50 |

|

2 |

50 |

50 |

50 |

50 |

|

3 |

200 |

50 |

50 |

50 |

|

4 |

200 |

200 |

200 |

200 |

|

5 |

400 |

200 |

200 |

200 |

|

6 |

500 |

400 |

200 |

200 |

|

7 |

500 |

400 |

400 |

400 |

|

8 |

800 |

400 |

400 |

400 |

|

9 |

1500 |

500 |

400 |

400 |

|

10 |

3000 |

500 |

500 |

500 |

|

11 |

Buff |

800 |

500 |

500 |

|

12 |

Buff |

800 |

800 |

500 |

|

13 |

|

1500 |

800 |

800 |

|

14 |

|

3000 |

1500 |

800 |

|

15 |

|

Buff |

1500 |

800 |

|

16 |

|

Buff |

3000 |

1500 |

|

17 |

|

|

3000 |

1500 |

|

18 |

|

|

Buff |

1500 |

|

19 |

|

|

Buff |

3000 |

|

20 |

|

|

|

3000 |

|

21 |

|

|

|

Buff |

|

22 |

|

|

|

Buff |

|

23 |

|

|

|

Buff |

|

24 |

|

|

|

Buff |

|

50-400# Metal disc 500-3000# Resin disc Buff |

||||

|

Any other sequence according to requirements |

||||

Product detail pictures:

Related Product Guide:

Adhering into the principle of quality, provider, performance and growth, we now have gained trusts and praises from domestic and intercontinental consumer for Excellent quality Grinding Plate - 200MM Resin Polishing Buff for Granite – Jingstar , The product will supply to all over the world, such as: Sydney, Bangladesh, Madras, If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.