China Cheap price Diamond Grit Polishing Pads - 3 -Step Wet Polishing Pads – Jingstar

China Cheap price Diamond Grit Polishing Pads - 3 -Step Wet Polishing Pads – Jingstar Detail:

DESCRIPTIOIN

Three steps wet polishing pads has high productivity. Polishing pads are easy to bend and very flexible which it is easy to polishing on all the edge and corner of stone slabs while workers are doing polishing.After completion of step 3 polishing pads, the operator can use the pad again at low RPM with a small amount of water to buff the final product.3 step polishing pads are goods for stone polishing, line chamfer, the arc plate and special-shaped stone processing. Three step polishing pads also be used for processing, repairing and renovating marble, concrete, cement floor, terrazzo, glass ceramics, artificial stone, tiles, glazed tiles, vitrified tiles etc. It will no leave any color on the stones or burn the surface of the stone slabs.

Welcome to write to us, we will provide you best polishing solution.

FEATURES

Only 3 steps from start to finish. Instead of 7 steps pads, you can save a lot of time and costs

High gloss, good durability

High gloss and good durability

No scratches and color left on the stone after grinding and polishing

Universal use for Polishing Granite, Marble, Engineer stones and other natural stones.

| Diameter | Arbor hole | Use | Thickness | Diamond grit |

| 4″/100mm | 16mm | Dry &Wet | 3mm | 1,2,3 |

| 4.5″/115mm | 16mm | Dry &Wet | 3mm | 1,2,3 |

| 5″/125mm | 16mm | Dry &Wet | 3mm | 1,2,3 |

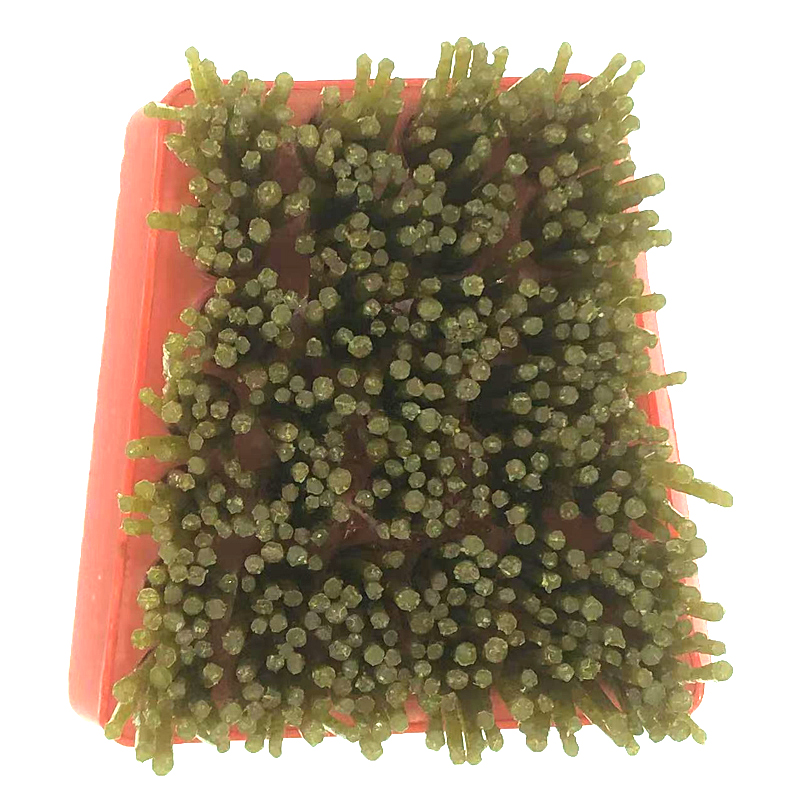

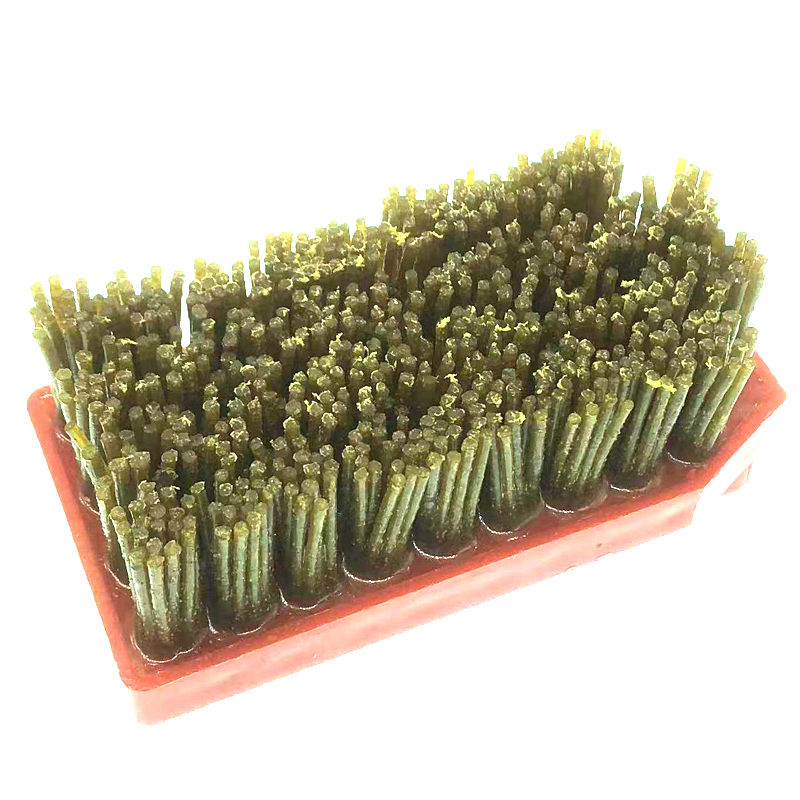

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction for China Cheap price Diamond Grit Polishing Pads - 3 -Step Wet Polishing Pads – Jingstar , The product will supply to all over the world, such as: Orlando, Swiss, Bahamas, With the spirit of high quality is our company's life; good reputation is our root, we sincerely hope to cooperate with customers from at home and abroad and hope to build a good relationship with you.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.